Artificial Reefs: What works and what doesn’t

Artificial reefs are one of the many tools used by marine conservationists to restore coral reefs around the globe, they are made from a variety of natural or synthetic materials, and come in an infinite number of shapes and styles. The goal of these artificial reefs is generally to provide a stable growing area for corals, and habitat for fishes and all the other organisms that you would find on a natural reef. Over the years, artificial reefs have a lot of praise from those who have worked with them, but a lot of criticisms from scientists who see it as working on the symptoms and not the problems that face coral reefs. At the New Heaven Reef Conservation Program, we have been working with artificial reefs for over a decade, and in this article, we are going to explore the history of artificial reefs, and then look at some of the methods we have found to be the most or least successful.

A Bit of Background

Indigenous cultures throughout the Indo-Pacific have been known to use bamboo and palm leaf structures in order to attract fish, known as fish aggregation devices or FADs. It is not known how long this practice has been going on, but it is safe to say that it is at least several thousand years old. In that same tradition, many of the first artificial reefs were designed as FADs or for increasing available fish habitat. Unlike many modern-day artificial reefs, these first artificial reefs weren’t intended to encourage the growth of these ecosystems, but instead were used as a tool to help us harvest more from them. A book written by John Holbrook in 1860 is one of the earliest publications on how to design and use artificial reefs to attract fish in an area that was damaged by on-land development. However, we are going to focus more on the artificial reefs for coral restoration, rather than those in temperate climates or used to increase fish catch rates.

Indigenous cultures throughout the Indo-Pacific have been known to use bamboo and palm leaf structures in order to attract fish, known as fish aggregation devices or FADs. It is not known how long this practice has been going on, but it is safe to say that it is at least several thousand years old. In that same tradition, many of the first artificial reefs were designed as FADs or for increasing available fish habitat. Unlike many modern-day artificial reefs, these first artificial reefs weren’t intended to encourage the growth of these ecosystems, but instead were used as a tool to help us harvest more from them. A book written by John Holbrook in 1860 is one of the earliest publications on how to design and use artificial reefs to attract fish in an area that was damaged by on-land development. However, we are going to focus more on the artificial reefs for coral restoration, rather than those in temperate climates or used to increase fish catch rates.

A lot of people attribute Charles Darwin with being the first reef restorationist, when he attached dislodged corals to bamboo stakes and observed that they were able to survive, unlike those that were left to roll around in the sands. Although not a very effective artificial reef (bamboo will degrade in water faster than the coral can lock it self in), it is a good example of how artificial reefs can be used to provide a safe and stable growing environment for corals. Although interesting, it was probably divers visiting sunken wrecks that first really noticed how artificial substrates can be transformed into thriving natural coral reef environments. From those roots, the idea took hold that we could actually improve the rate of succession and recovery of ecosystems after they were damaged by providing the structure that corals and sponges need, and the habitat for the fish and invertebrates that all play a roll in keeping the ecosystem healthy and functioning.

In the beginning, when artificial reefs first started being used for the restoration of coral ecosystems in the 1970’s-1980’s, a lot of the structures that were sunk were those that were readily available, such as old boats, decommissioned military ships, train cars, vehicles, etc. Many of these worked well, if they were stable, non-toxic, and structurally diverse. Unfortunately, at the same time, others saw artificial reefs as a way of disposing of waste without paying the required fees and even getting some recognition as a responsible business. Such examples include mixing dry industrial waste or ash into concrete, dumping of millions of tires into the sands, and the use of construction waste in places like Singapore. These later examples set-back the field of artificial reefs for many years, and still today are used by scientists to argue against their applicability in protecting marine resources.

Luckily for reefs however, most conservationists recognize that those bad examples are just part of the learning curve, and that things have come a long way since those days. Today, instead of using just materials of opportunity or waste, most artificial reefs are purposefully designed and deployed using long-lasting and non-toxic materials that provide a high degree of surface and structural diversity. Today, we generally recognize several main goals for artificial reefs:

- Replace structure and habitat diversity in places where it has been lost (due to dredging, development, storms, bleaching, etc.)

- Increase the size of reefs or available structure to enhance local marine resources and improve biodiversity

- Create artificial dive/snorkeling sites to relieve tourism pressure on natural reefs

- Create attractive or art inspired reefs to increase awareness and communicate reef issues to the general public

It is important to recognize that artificial reefs only work in areas where water quality is still conducive to coral growth. Artificial reefs are a great tool of marine resource managers, but it is only one tool on our belt. It needs to be used in conjunction with a wide variety of other actions such as establishing rules and regulations, reducing local land and sea based threats, reducing over-fishing/over-use, and other mitigation or protection methods to create an effective and holistic coral reef restoration program.

What doesn’t work

There are many factors that can make an artificial reef a success or failure, and even the same techniques and materials may work well in some situations and not in others. A complete description of the materials, techniques, and environmental factors to consider is a lot more than can fit in one article, which is part of the reason why we offer extended courses on the topic. However, below are some of the techniques we or others have tried that have failed, and a bit about why. Despite not working, we do see people repeating these same mistakes all the time while ‘trying to reinvent the wheel,’ so this is an important place to start.

1. Trash and potentially toxic materials

It should be a given, but we still see this going on today. Waste materials are rarely good for building reefs as they tend to be too small and not stable for organisms to grow on them. They often leach toxic chemicals or do not provide the surface micro-structure needed for organisms to latch onto. The most famous example of this is the Osborn reef built in Florida in the early 1970’s, which saw around 2 million old tires dumped onto the sea bed. 30 years later, studies showed that almost no fish were living in the area, the tires were leaching toxic chemicals, and with each storm they were moving all over the sea bed (some were found washed ashore as far away as North Carolina). Identical projects were also carried out in Indonesia, the Philippines, and Australia in the 1980’s

Today’s equivalent to these tire projects is probably best exemplified by those utilizing PVC or plastics. Throughout SE Asia, PVC pipe companies often sponsor these projects, contributing to their popularity. However, time and time again these so called artificial reefs are found to move or overturn in even light storms, break apart, and eventually start to degrade and release toxic chemicals. Furthermore, blue and green PVC has a smooth surface that corals will not readily recruit or attach to, and so it never ends up looking like a natural reef. Another example was a study by Dr. Laurie Raymundo in Guam following blast fishing, in which PVC mesh was laid out on the destroyed reef and transplanted with coral. Results looked promising at first, but at the 2010 APCRS Dr. Raymundo showed pictures of the area, no corals had attached and for the most part the mesh was making a mess of the area and was later removed.

2. Small/unsecured structures

2. Small/unsecured structures

The main goal of artificial reefs is to create solid structure, however that aim seems to get lost in some artificial reef projects. The classic example of this is using construction blocks (aka breeze or cinder blocks), which are literally designed to be lightweight and easy to break in half. Despite these attributes, the fact that they are cheap and readily available anywhere in the world has made them popular, albeit largely unsuccessful technique. Generally, these are utilized during very large government or corporate projects, using volunteers who drill holes in the blocks then epoxy coral fragments into the holes. Divers then place them in ‘mats’ on the reef or sand areas. They look great in the first few sets of pictures, but after the first small storm or monsoon season they generally can be found scattered across the reef edge or partially buried in sand, with few to none of the coral fragments still alive. There have been some very creative and elaborate attempts to lock up or create larger units out of the blocks using ropes or rebar, but the old axiom of ‘garbage in, garbage out’ usually holds true.

Although far from a comprehensive list, these are some of the most popular ways that folks unfortunately set themselves up for failure. But don’t think failure is ubiquitous amongst artificial reef projects, because every year new and exciting techniques, materials, and designs are coming out that are proving their applicability.

So, What Does Work?

As you have probably gathered by now, an ideal artificial reef is:

- Stable in normal to large storms

- Made from long-lasting, solid, non-toxic materials

- Designed to have a high surface complexity (texture) for the recruitment of corals, sponges, and other organisms

- Designed to provide a high amount of structural complexity for fish and other animals

- Designed to either blend in with the natural reef, or be designed to stand out and convey a message (sculptures and art)

Again, considerations such as depth, placement, boat navigation, etc. are not discussed here, but are vitally important to success. Below we will look at some examples of artificial reefs we commonly work with and comment a bit on why we like these techniques, even if they might not fulfill all 5 of the criteria above.

1. Wrecks and other large steel structures

1. Wrecks and other large steel structures

Metal ship wrecks are some of the oldest and most well developed artificial reefs, even if there resting location was not planned. Warships from World War I and II provide some of the most stunning examples of how the ocean can claim man-made structures and create a living ecosystem out of a foreign object. In some cases, old wrecks are so covered in corals and marine life that they have only been identified through advanced technologies such as LIDAR, or by accident during drilling or dredging operations.

Coral reef organisms grow well on steel structures, despite the concerns of some that iron and other limiting nutrients will favor algal or bacterial growth. Although utilizing materials of opportunity, purposefully sunk wrecks do however require environmental and safety preparations before being deployed. In addition to wrecks, but along the same lines, are the use of decommissioned oil platforms as artificial reefs, providing that proper environmental preparations are completed first, these structures can provide amazing ‘islands of biodiversity’ in otherwise barren seascapes.

It should be noted however that using mixed metal alloys is much less effective than steel structures. Due to the effects of electrolytic degradation that occurs between different metals when placed in a salt water solution, items such as cars, helicopters, or airplanes will degrade and break apart in only a few short months.

2.Concrete structures

Concrete is the favorite material to use for most reef managers for many reasons. First, it is a material that is very close in composition to natural coral limestone, and also it is strong, heavy, cheap, and readily available all over the world. Concrete can be made into nearly any shape or size, and lasts a long time under the ocean. Some critics claim that trace metals found in concrete (aka Portland cement) will cause coral disease, but this is never realized in the ocean, and in our experience, corals thrive on these structures. The main draw back to using concrete is that structures can quickly become too heavy to deploy using the limited resources that most small reef managers have available. Some of our largest concrete projects (i.e. Buoyancy World, Mini Square, the DMCR Cubes, etc.) have only been possible because of partnerships with the government, which has allowed us access to large barges.

3. Modular units made of Steel rebar, Cement, or glass

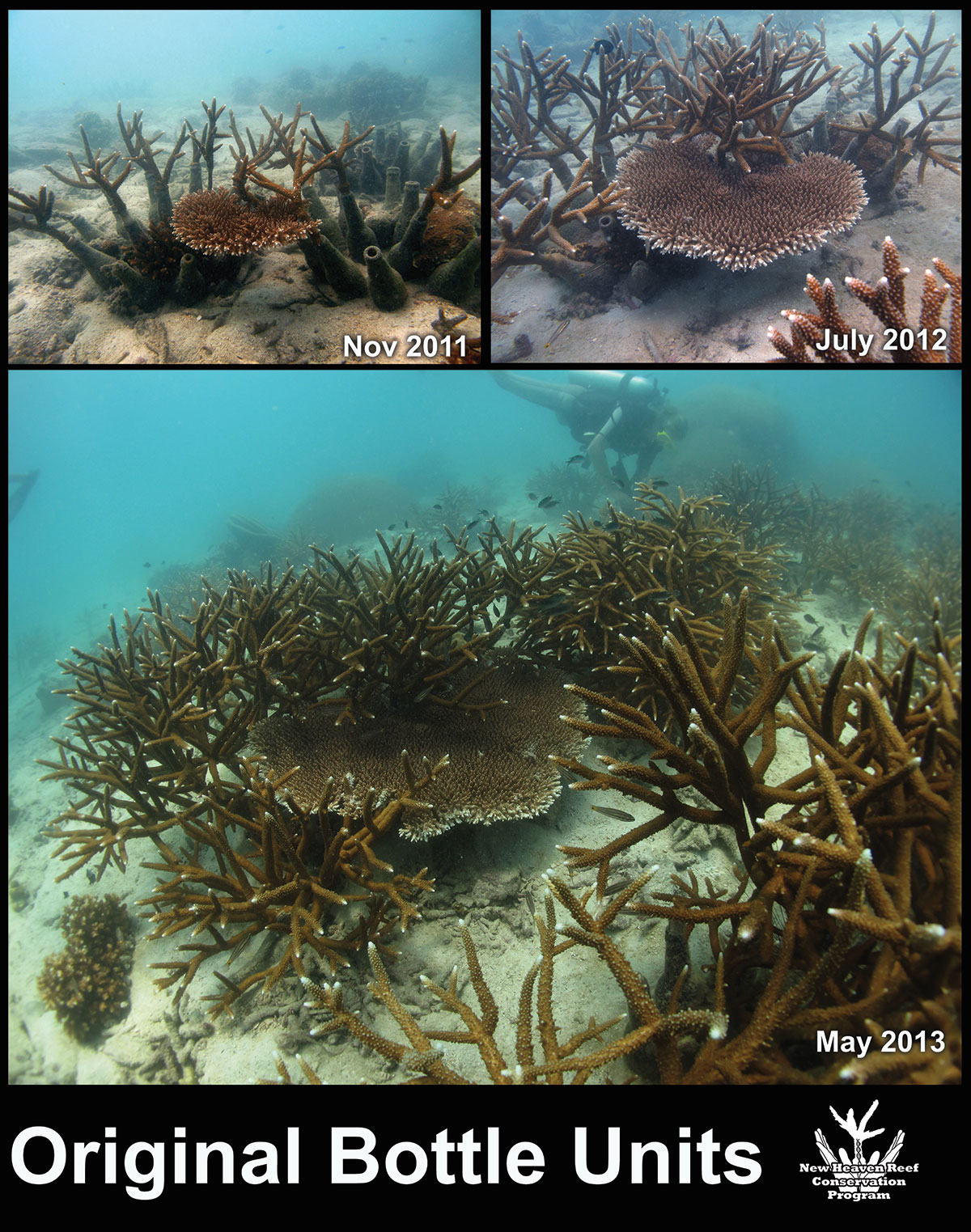

Some of our favorite structures are smaller units that are easily deployed (light enough to be carried to a boat by volunteers) and then assembled into larger structures underwater. Suan Olan is one of our best examples of this, were we have some structures made out of prefabricated concrete parts assembled into interesting and sometimes interactive structures. We also have many of our Bottle Units there, which has been one of our most successful techniques to date. The units consist of a concrete base, into which glass bottles are placed and become the securement point for corals. The units are sunk into the sands to prevent them from moving around. Lastly, we have there many of our metal structures that are made from rebar. Providing these structures are kept small, rigid, and properly welded then they do really well. They provide an easy place to attach corals, tend to allow waves to pass through them to prevent overturning, and last about 8-10 years underwater. Once they do collapse, they are usually so covered in coral that things just keep growing as normal.

4. Mineral Accretion devices

4. Mineral Accretion devices

Probably the most exciting method of artificial reef construction is the use of mineral accretion devices, or electrified artificial reefs (traditionally known as Biorock™). These start off just like our modular metal structures made of rebar, but once in the water low voltage electricity is passed through the structure. This creates an effect known as electrolysis, which provides cathodic protection to the structure (prevents it from rusting or corroding), and furthermore causes minerals from the sea water to precipitate out and collect on the metal. This action creates a beneficial environment for the growth of corals and other calcium carbonate secreting organisms, which tend to grow much faster on these structures (up tp 3-5 times) and survive better through disturbances such as temperature induced bleaching. Traditionally, these units have been very expensive and required a high amount of maintenance and expertise. However, we are working together with our partner CoralAid to modernize and revolutionize this technology so that more reef managers can utilize it.

Over the last few years, more and more interesting or novel methods materials are being designed, some of which show a lot of promise. These include the use of 3-D printers to create structures with exponentially greater surface and structural diversity that could be achieved through traditional means, and the increasing use of art and sculpture to draw more awareness to the plights of the ocean. For years, artificial reefs have been seen as mis-directed efforts or ‘mindless meddling.’ And there are many examples of where folks have gone for the attractive and media savvy route of building artificial reefs without focusing on actually solving the problems in their area. Such efforts will always end up in failure. However, more and more data and anecdotal evidence is showing that artificial reefs can and should be a part of an integrative and holistic reef management program.